In a new study, researchers at North Carolina State University have shown that they can print layers of electrically conductive ink on polyester fabric to make an electronic textile that could be used in the design of future wearable devices.

Since the printing method can be performed at room temperature and under normal atmospheric conditions, the researchers believe that inkjet printing could offer a simpler and more efficient method of manufacturing electronic textiles, also called e-textiles. Additionally, the researchers said the findings suggest they could extend techniques common in the flexible electronics industry to textile manufacturing. They reported their findings in the newspaper Applied materials and interfaces ACS.

“Inkjet printing is a new and rapidly evolving technology that is used in flexible electronics to make films used in cell phone screens and other devices,” said the corresponding author of the study, Jesse S. Jur, professor of textile engineering, chemistry and science at NC State. “We believe this printing method, which uses materials and processes common in the electronics and textile industries, also holds promise for manufacturing electronic textiles for portable devices. “

In the study, the researchers described how they used a FUJIFILM Dimatix inkjet printer to create a durable and flexible electronic textile material, which they did to reliably create electronic textile and its properties. Part of their challenge was finding the right composition of materials so that liquid ink didn’t seep through the porous surface of textile materials and lose its ability to conduct electricity.

“Printing electronic textiles has been a very big challenge for the electronic textile industry,” said the study’s first author, Inhwan Kim, a former NC State graduate student. “We wanted to build a structure layer by layer, which was not done on a textile layer in inkjet printing. It was a big struggle for us to find the right composition of materials.

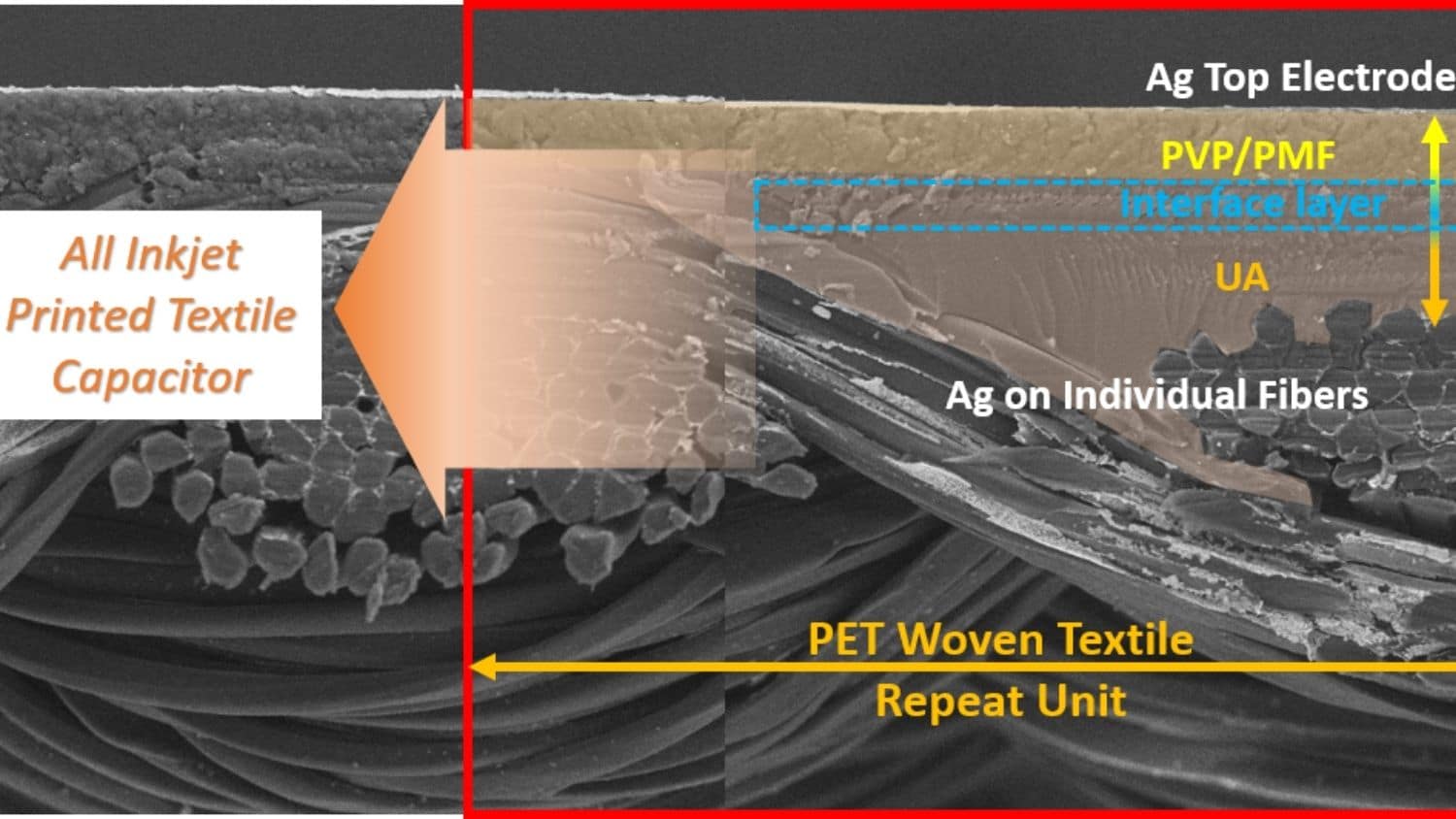

They created electronic textile by printing layers of electrically conductive silver ink like a sandwich around layers of two liquid materials, which acted as insulators. They printed these sandwich layers on a woven polyester fabric. After printing the layers of silver ink and insulating materials – based on urethane-acrylate and poly (4-vinylphenol) – they monitored the material’s surface using a microscope. They found that the chemical properties of insulating materials, as well as textile threads, were important in maintaining the ability of liquid silver ink to conduct electricity and prevent it from penetrating through porous fabric.

“We wanted a tough insulation layer in the middle, but we wanted to keep it as thin as possible so that the whole structure was thin and the electrical performance was as high as possible,” Kim said. “Plus, if they’re too bulky, people won’t want to wear them.”

The researchers evaluated the electrical performance of electronic textile after bending the material several times. They tested over 100 flex cycles and found that electronic textile had not lost its electrical performance. In future work, they want to improve the electrical performance of materials compared to e-textiles created using methods that require special installations and atmospheric conditions, as well as increase the breathability of the material.

Eventually, they want to use the printing method to create an e-textile that could be used in portable electronic devices such as biomedical devices that could track heart rate, or used as a battery to store energy for devices. electronic.

“We were able to coat the ink on the fabric with a multi-layered material that was both durable and flexible,” Kim said. “The beauty of it all is that we did it all with an inkjet printer – we didn’t use any lamination method or anything. “

The study “Microstructures in All-Inkjet Printed Textile Capacitors with Bilayer Interfaces of Polymer Dielectrics and Metal-Organic Decomposition Silver Electrodes” has been published online in Applied materials and interfaces ACS. In addition to Jur and Kim, the other authors were Beomjun Ju, Ying Zhou and Braden Li. It was funded by VF Corporation. The authors also thank Liquid X Printed Metals for preparing the reactive silver inks used in this study. The authors thank the United States Department of Defense and the Air Force Research Laboratory for awarding the Science Mathematics and Research for Transformation (SMART) scholarship to Li. This work was supported by the National Science Foundation by the through the Nanosystems Engineering Research Center for Advanced Self Powered Systems for Integrated Sensors and Technologies (ASSIST) under EEC grant 1160483.

-oleniacz-

Note to editors: The summary follows.

“Microstructures in textile capacitors entirely printed by inkjet with bilayer interfaces of polymer dielectrics and metal-organic decomposition silver electrodes”

Authors: Inhwan Kim, Beomjun Ju, Ying Zhou, Braden M. Li and Jesse S. Jur

Posted published May 14, 2021 in ACS applies materials and interfaces.

DO I: 10.1021 / acsami.1c01827.

Abstract: Soft printed electronics feature unique structures and flexibilities suitable for a plethora of portable applications. However, the formation of scalable and reliable multilayer electronic devices with heterogeneous material interfaces on soft substrates, especially on porous and anisotropic structures, is very difficult. In this study, we demonstrate an all-printed textile inkjet capacitor using a multilayer structure of bilayer polymer dielectrics and particle-free organometallic decomposition (MOD) silver electrodes. Understanding the inherent porous / anisotropic microstructure of textiles and their surface energy relationship was an important step in the process for successful planarization. The MOD silver ink formed a fundamental conductive layer through the uniform encapsulation of the individual fibers without blocking the fiber interstices. The urethane acrylate and poly (4-vinylphenol) bilayer could form a flattened dielectric layer on polyethylene terephthalate (PET) textiles. A unique chemical interaction at the interfaces of bilayer dielectrics has played an important role in the insulation of porous textile substrates, resulting in high chemical and mechanical durability. In this work, we demonstrate how the unique textile microstructures and bilayer dielectric layer designs improve the reliability and scalability of the inkjet process as well as the use in portable electronics with electromechanical performance.